The NextFEM Designer scripting engine combines ease of implementation with power and accessibility of results. In this article we develop a few-line script to scroll through the base plates of a scaffold .

NextFEM Designer, through the Struct module, supports the calculation and verification of scaffolding and temporary structures. Scaffolding checks are carried out according to EN 12810 and 12811, at different levels:

- Local verification of the beams , for 3 sections of each scaffolding rod

- Check local of joints scaffolding, see www.nextfem.it/it/2542-2/

- Check overall in rollover , see www.nextfem.it/it/overturning-checks-in-scaffolds/

- Verifications in sliding and uplifting, as described below.

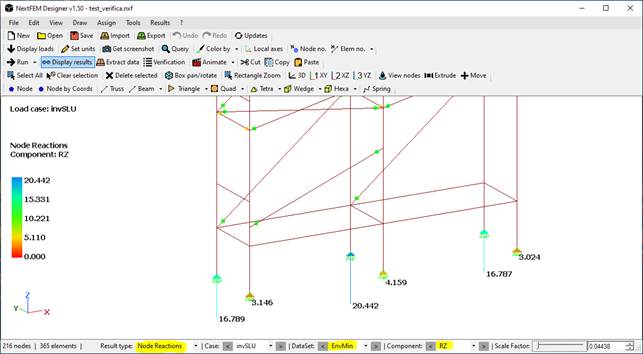

The uplifting check is considered satisfied when none of the base plates works in tension, i.e. it occurs through the linear model that no base plate is uplifted, under every combination. This is a check that can be carried out locally: the base plates are represented in the model by supports, and therefore it is sufficient to check for each of the minimum envelopes of the load combinations (at the Ultimate and Exercise Limit State) that the vertical reactions of the basic constraints are always positive, as in the following figure.

The total sliding check is carried out by checking that the scaffolding does not slide on its horizontal support plane, that means there are no slips at the interface between the base plates and the ground.

The adjective "total" reminds us that it’s a global verification. Unless there are force compensations between the base plates, the check can also be carried out locally, making sure that each individual plate is always compressed with an effort that will generate a friction effect at the interface with the ground that is higher than the transmitted shear force.

In terms of modelling results, it will be sufficient to compare the base shear with the product between a friction coefficient (chosen appropriately by the user) and the axial stress.

The friction coefficient depends on the roughness of the surfaces in contact, i.e. base plates and ground: an appropriate and conservative value in case of normal use is 0.2. This coefficient is dimensionless, since it represents the ratio between tangential and normal stresses (and, by extension multiplying by the same area, between axial force and shear).

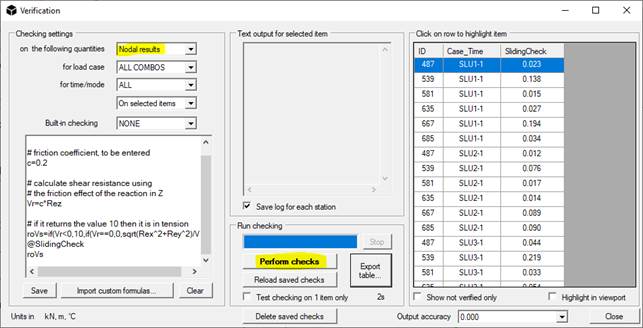

Using the NextFEM Designer scripting engine, accessible from Results / Verification…, it is possible to carry out the lifting and sliding checks for each constraint in an automated and rapid way.

By entering the script below and using the results in terms of constraint reactions:

# script for sliding check

# friction coefficient, to be entered

c = 0.2

# calculate shear resistance using

# the friction effect of the reaction in Z

Vr = c * Rez

# if it returns the value 10 then it is in tension

roVs = if ( Vr <0.10, if ( Vr == 0.0, sqrt (Rex ^ 2 + Rey ^ 2) / Vr ))

@SlidingCheck

ROVs

We get the results for each constrained node in the model that has a vertical reaction:

With just 3 formulas, the script

allows automatic verification of sliding and lifting, marking the lifting of

each base plate with the Demand / Capacity D/C ratio of 10. If, on the

other hand, the "SlidingCheck" ratio is less than 1, the base plate

does not lift or slide for that combination.

The

script can be used by dragging the text file into the white box to the left of

the previous mask, or copied to the program installation folder,

"verification" subfolder.

The power and ease of use of NextFEM Designer allow the easy realization of customized and limitless checks.